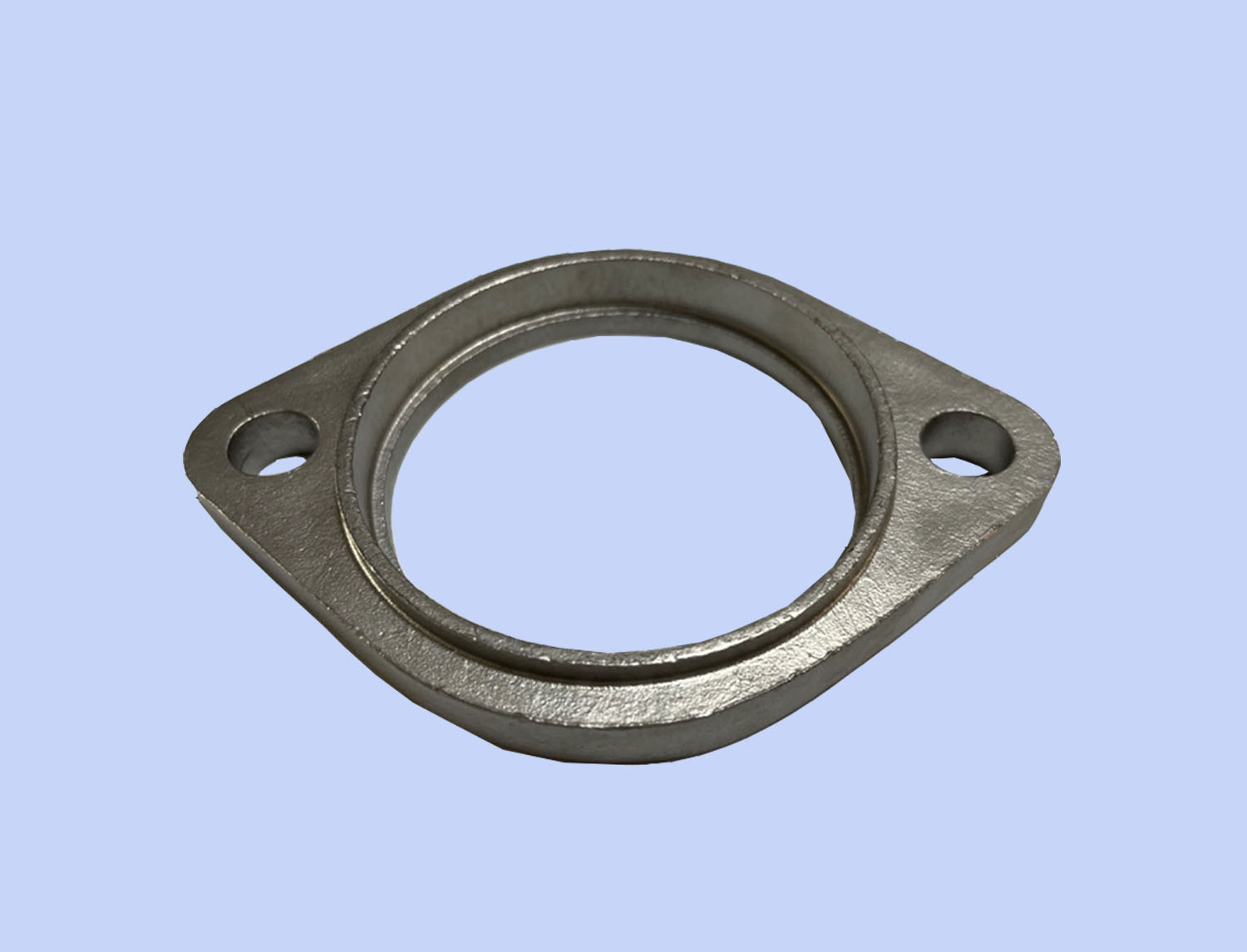

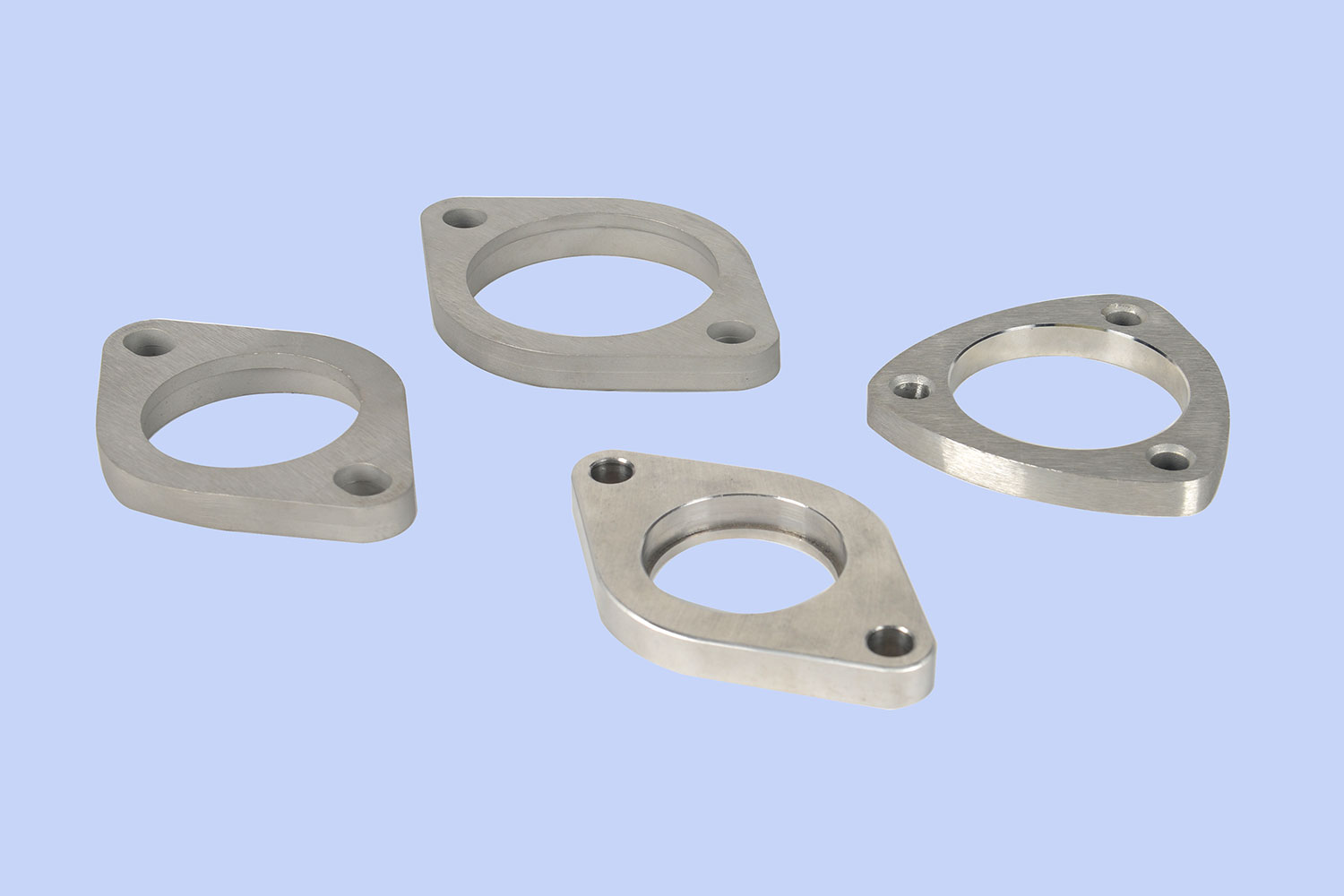

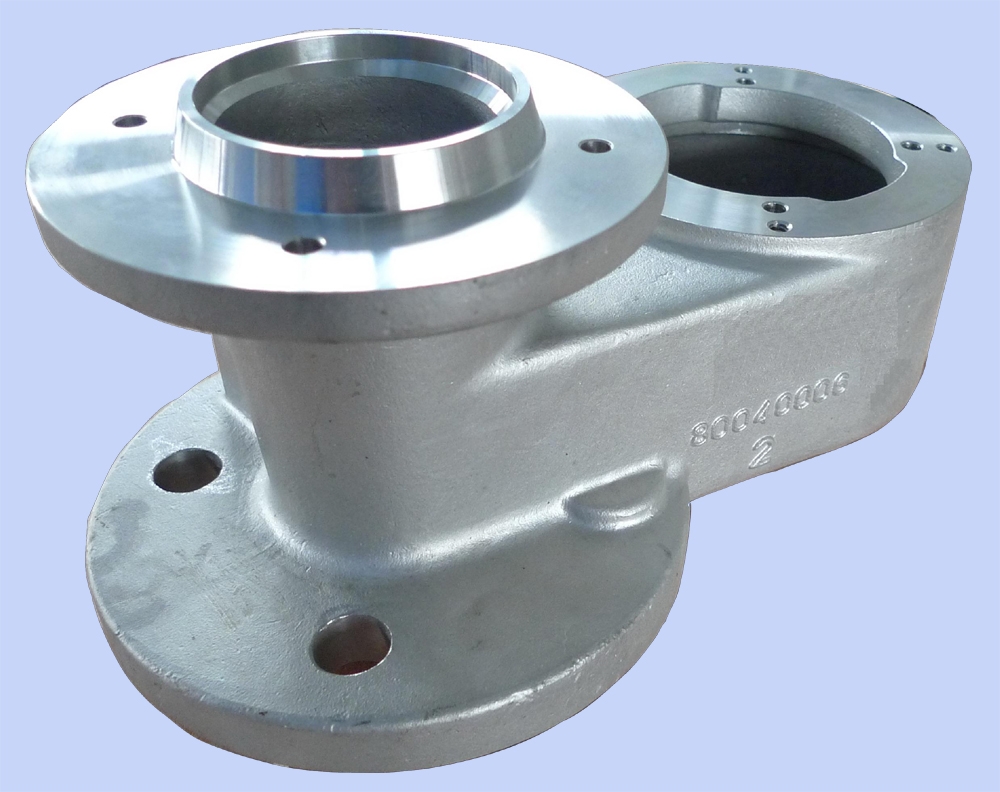

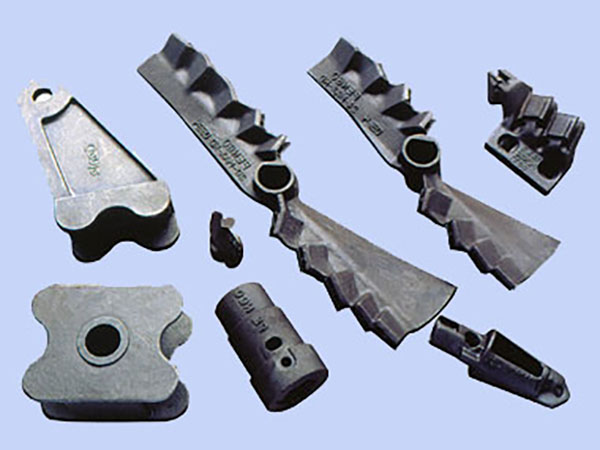

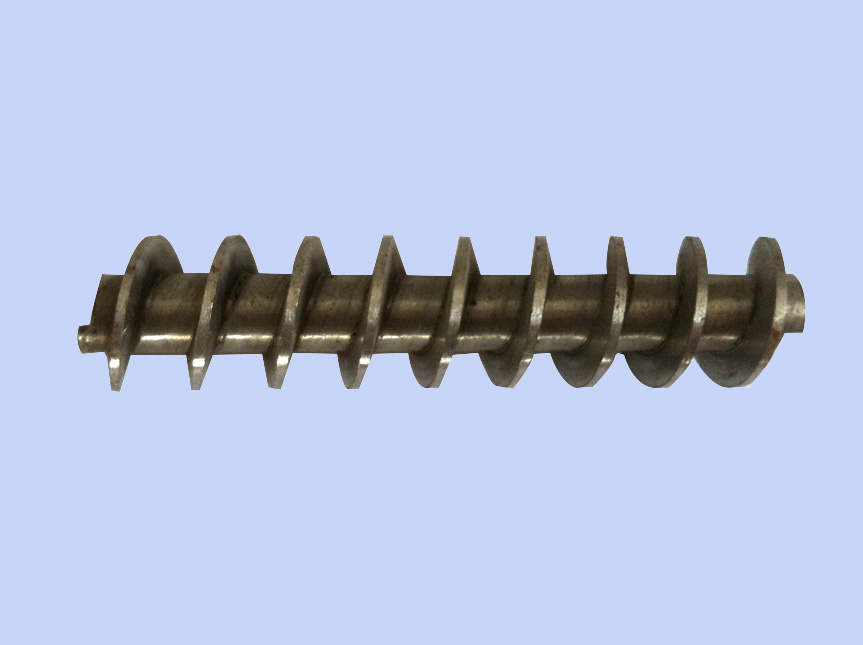

Investment casting Also known as Lost Wax Casting, is a process that has been one of the oldest known metal forming techniques. When wax formed the pattern in today's high technology waxes, refractory materials form the shell and specialty alloy castings produced ensures high-quality components with accuracy, repeatability, versatility and integrity. The process is suitable for repeatable production of net shape components from a variety of different metals and high performance alloys. Investment casting can incorporate intricate contours, and in most cases the components are cast near net shape, so it requires little or no rework after cast. Mold cost is in between sand & die casting but surface finish is better than sand casting, but not as good as die casting.

Material Chart:

Stainless Steel, Carbon Steel, High Tensile Alloy Steel